Hagans Plastics specializes in providing plastic solutions for a changing industry that include molding, thermoforming and other precision services.

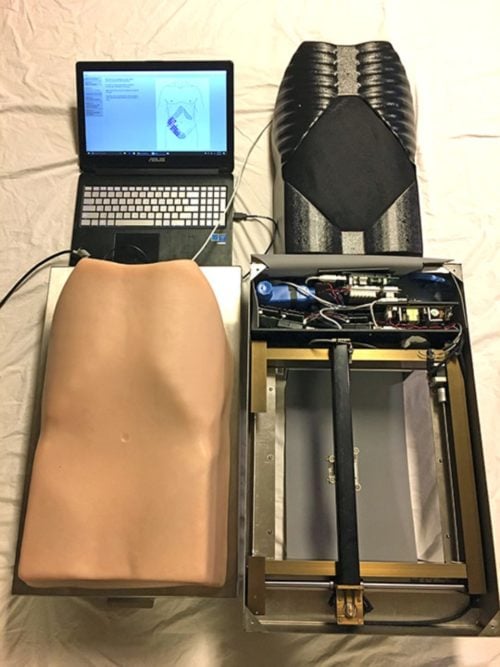

ACDET’s AbSim is an advanced medical training simulator that teaches student doctors and nurses how to perform a physical abdominal palpation exam. AbSim and its accompanying software are able to provide step-by-step tactile, visual, and auditory feedback as the student uses his or her hands to press and explore the abdominal region for signs of major ailments that typically require years of practice to acquire equal diagnostic experience. A student may independently use the software to practice location and detection of various ailments and practice cases with findings.

The simulator features a realistic skin and skeletal layer made from ABS plastic and formed by Hagans Plastics, and pressure into the abdomen is met with on-screen responses first showing how to palpate to a safe depth and coverage (with patients’ auditory responses if the palpation is too painful!), and physical resistances at two different depths within the abdominal area representing muscular guarding above and enlarged organs below, Many cases are provided, automatically changing ailment conditions and locations, teaching each and then challenging the student to diagnose them blindly with written case findings.

Finally, AbSim’s software also equips trainers with assessment and recording capabilities to use for evaluation of student progress. To learn more about this project, contact us today.

Vacuum Thermoforming of Custom Seat Backs for the Aerospace Industry Project Highlights

| Product Description | Body Shell |

| Capabilities Applied/ Processes | Primary: Thermoforming |

| Expertise | Customer supplied Mold: Refit and customize to our machines |

| Overall Part Dimensions | 14.00 long x 23.00 wide x 6.00 tall |

| Material Used | .187 ABS, per customer specs |

| Material Finish | Haircell up, Standard Finish |

| Industry for Use | Medical |

| Volume | Initial of 25 |

| Standards Met | Customer Specifications |

| Product Name | Body 101 |