Founded in 1973, at Hagans Plastics Co., Inc. we have grown into a leading custom former and injection molder with an extremely diverse customer base, from large corporations to garage shop inventors.

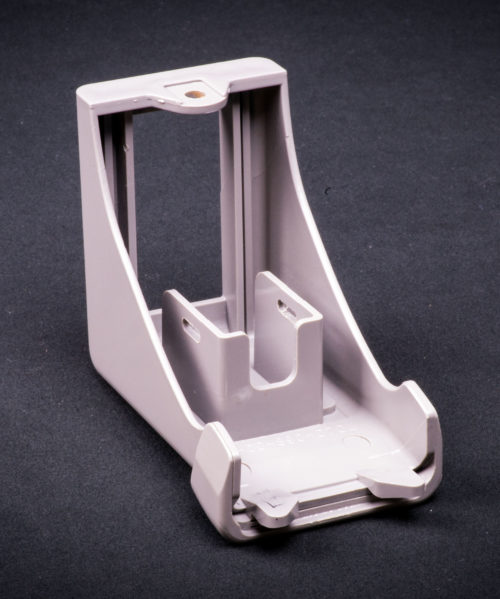

Our success is built on our continued development as a full service, custom injection molding provider with a variety of advanced injection molding systems. Our manufacturing facility is equipped with injection molding equipment that utilizes advanced robotics, and can deliver up to 200 tons of pressure with shot sizes of up to 20 ounces. These machines are designed to mold most commercially available engineered resins and a majority of commodity resins, including acrylic, nylon, thermoplastic, and many others. Our injection molding operation is geared for short to low volume runs, however, we also possess the flexibility to provide the same efficiency and low cost for high volume production, and offer a stocking program to further accommodate volume production requirements.

With the capability of 5 axis CNC machining, we can provide even greater flexibility and cost savings with the ability to machine certain secondary features into parts. This eliminates the need to add expensive core pulls or slides to the mold. This is enhanced by the fact that we don’t outsource, and all tooling is built in the United States. Our team of skilled technicians and machinists can perform a number of additional tasks, from drilling and riveting to deburring, engraving, and polishing. This makes our services ideal for parts used in industrial equipment, the food industry, aerospace applications, and much more.

At Hagans Plastics, we take quality seriously; all work is performed to AS9100 and ISO 9001 standards, and is also subject to our own stringent quality program. To learn more about our injection molding services, contact us.