Design Assistance and Prototyping

Hagans Plastics will review your design and assist you with optimizing it for the forming process. If you do not have a design we can help you connect with our design partners.

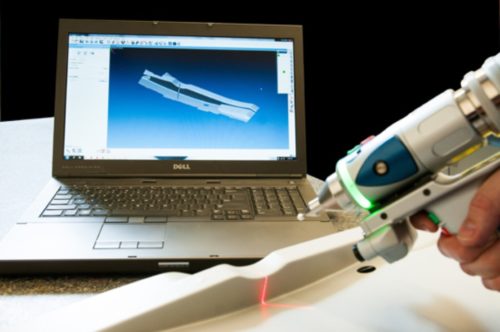

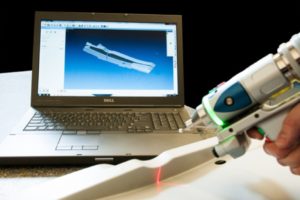

If you have a sample or existing product without 3D data it can be laser scanned with our Faro Arm and converted into a 3D model using our Polyworks software. Once we have the 3D data, prototype tooling can be created using our MasterCam software and 5-axis CNC routers. Prototype tooling is a cost-effective alternative for creating samples or short production runs to prove out your design.

Our number one goal is to make sure our customers are successful with their design.

Engineering

- Manufacturing Process Optimization

- Design Review & Recommendations

- Reverse Engineering: FARO HD Laser

- 3D modeling: Solidworks, MasterCAM

- Ability to work with virtually any type of file

- Fixture design and manufacture

- Sales Fantasy realization

Tooling

Master Pattern, Prototype, and Hard Tooling, Fixtures

In the early days, most tooling was created in wood by pattern makers, there are times when this still is a cost-effective solution. We continue to maintain a complete pattern shop while also adding new technology to it. New technology added includes laser scanning, 3D modeling, and 5-axis CNC machining. State-of-the-art equipment enables us to CNC machine tooling out of wood, RenShape or aluminum plate. Our tooling shop has the ability to design and create support tooling (CNC Router fixture, drill fixtures, bending fixtures, and assembly fixtures) as needed in-house.

Hagans Plastics’ numerous years of experience and the needs of our customers help us determine the correct solution. Having these solutions in-house reduces lead times and provides a cost-effective resolution.

Assembly

Hardware, Velcro, Secondary Finishing for Vacuum Formed Parts

After a part is formed and trimmed it is not uncommon for some assembly work to be required. With our complete fabrication area, we can add snaps, Velcro, latches, and hinges to your part. Our capabilities also include sonic welding, solvent bonding, using various adhesives and applying VHB tape.

Our goal is to supply completed parts to our customers for immediate use upon receipt.