At Hagans Plastics Co., Inc., we have met the growing demands of our customers through our advanced technology in tooling, manufacturing, production, equipment, and most importantly, quality.

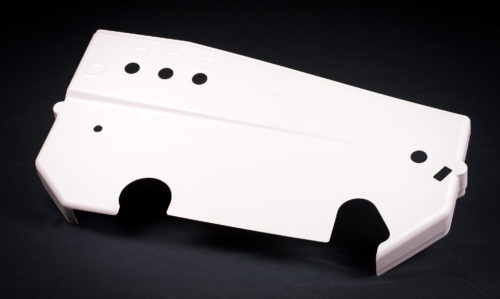

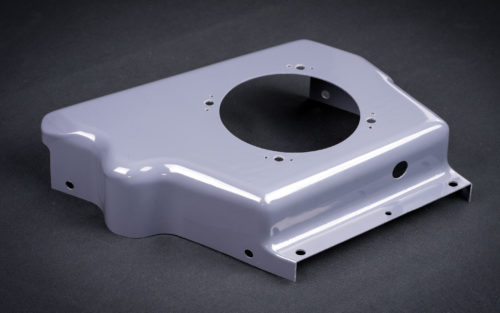

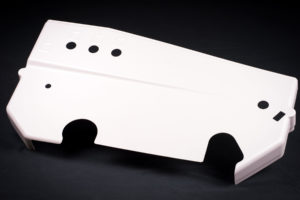

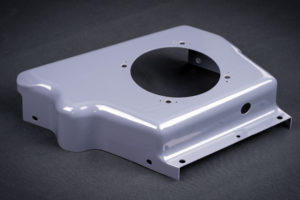

Our vacuum and thermoforming services are a cornerstone at Hagans Plastics and represent over 40 years of commitment to producing parts and components with unsurpassed quality.

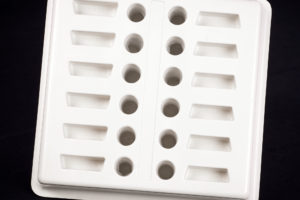

Vacuum and thermoforming utilize a process where a flat sheet of thermoplastic material is heated, followed by the application of vacuum pressure which pulls the material over or into a mold. The key advantages of vacuum forming as compared to other processes are a lower tooling cost and a quicker turn-around time. This makes the process ideal for prototyping, R & D, and depending on the product produced, it can also be a viable solution for long term volume production.

As specialists in vacuum and thermoform manufacturing, our facility is equipped with a wide range of state-of-the-art equipment. These systems can form parts as small as 1″ to 2″ all the way up to 5.5′ by 8′, with a thickness of 0.02″ to 0.5″, with both single and twin sheet forming, as well as heavy gauge forming. Parts can also be manufactured with options such as color, texture, translucent and transparent finishes.

To stay on top of this competitive market we are continually investing in state-of-the-art equipment and systems. We operate equipment that utilizes 1000-watt quartz heaters that have instant on, instant off capabilities. The efficiency of this type of heater means faster cycle times which equates to lower cost.

With over 40 years of industry experience, we understand that material selection is very important; regulatory requirements such as UL and FAA burn ratings are common factors that we deal with daily. We will work with you to provide the best material for your application. As a single-source solution, at Hagans Plastics we also offer the secondary services that provide you with a complete part. Our seasoned staff can perform related services including deburring, light assembly, and edge polishing.

From aerospace, automotive, and electronics to agricultural, construction, and the medical industries, at Hagans Plastics, we specialize in quality products and value-added services. To learn more about our vacuum forming and thermoforming services, contact us directly. Watch our Vacuum Thermoforming video here.

Case Studies See all

Molding Processes

- Pressure Forming

- Vacuum Forming

- Single Sheet

- Twin Sheet

Materials

- ABS

- Acrylic

- HIPS

- KYDEX®

- LEXANPET

- Ultem

- PVC

- Styrene

- Polycarbonate

Dimensions

Length

- Min: 2 in

- Max: 10 ft

Width

- Min: 1 in

- Max: 6 ft

Thickness (Base Material)

- Min: .02 in

- Max: .5 in