Aerospace

Hagans Plastics has been supplying component parts to one of the most demanding, regulated and safety-conscious industries in the world. From seatbacks to armrests to cockpit panels, Hagans can provide the expertise to get your project off the ground. Hagans Plastics is AS 9100 certified.

Cargo Door Cover

Thermoformed with KYDEX® 100 to match other interior components of the aircraft. The large mold needed for this (4’ x 5’) mechanical covering, highlighted the large scale capabilities of Hagans Plastics Company.

Medical

Medical device parts demand quality, form and function. From the smallest device to a large equipment cover, Hagans Plastics can meet your needs. Let us discuss our Pressure Forming capabilities and show you that you can receive parts similar to injection molding but with a shorter lead-time and at a reduced cost of tooling.

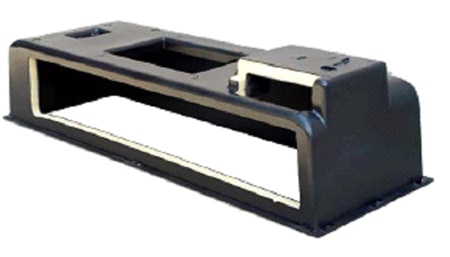

Blood Analysis Unit

Multiple process Noryl component designed with an outer panel and inner panel. Each was hand assembled prior to high pressure injection of insulation, and then CNC trimmed for precise enclosure fit.

Food Service

Hagans Plastics’ forming quality services have put quality parts in the food service industry.

Point of Purchase

Do you need a 6′ medical beaker, of a 3′ eye dropper or a costume head. Hagans Plastics will work with you to make sure that your creative ideas are made into reality.

Transportation

From cars to RV’s to boats and even golf carts, Hagans Plastics has supplied parts to some of the largest companies in America. They know that quality is paramount and that is why they choose Hagans.

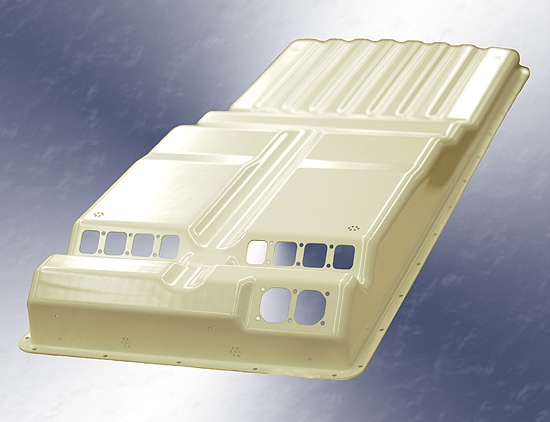

Coach Dash Assembly

Hagans Plastics Company produced a total of 18 components for this dash assembly beginning with the dash itself. The dash was Vinyl covered ABS. Other components included vents, cup holders, and the instrument panel.

Technology

Let our advanced technology protect or enhance your technology.

From Radomes to EMI Shielding, Hagans Plastics can work with you to develop a part that will satisfy all of your requirements.

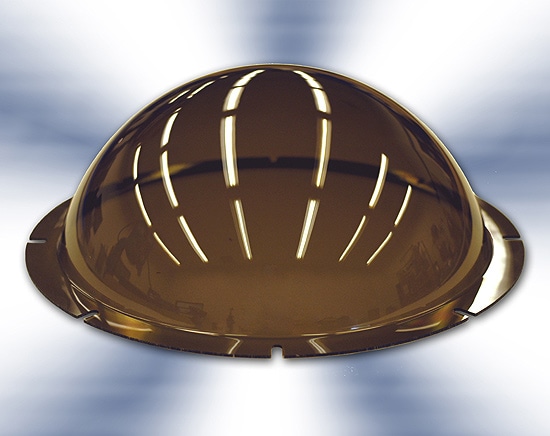

Radome

KYDEX® 100 thermoformed to allow microwave signals to pass through protective weather covering.

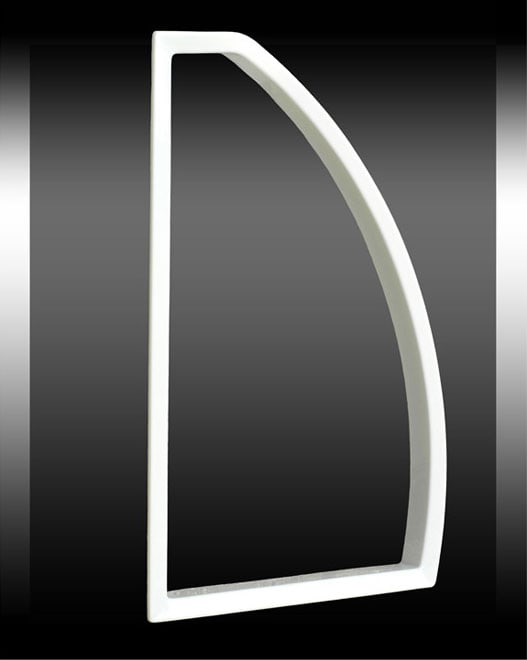

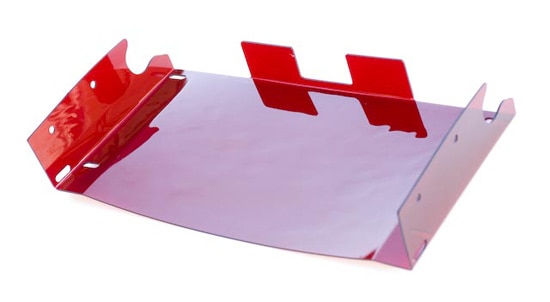

Vacuum Formed Flat

A “bowed” center specified by the designers with the added necessity of connector holes / tabs and 90 degree bends could have required multiple tooling. Hagans Plastics Company, however, used one tool.

The product was vacuum formed, CNC drilled and trimmed, with the sides hand formed in order to provide integrity to both thickness in bend and Drilled/trimmed attributes.