Hagans Plastics Co., Inc. offers additional services to include up-stream assembly of parts by our trained staff. Quality and service are Hagans Plastics priorities.

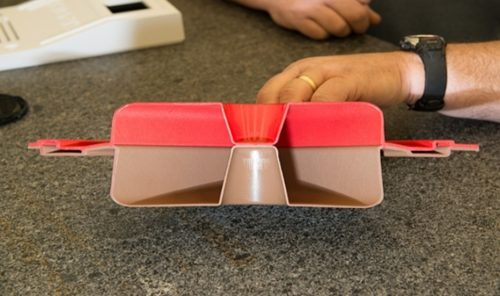

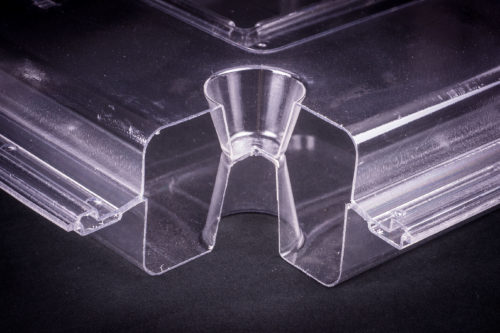

Twin Sheet Forming is often used as a higher quality alternative to rotational and blow molding. This process is used when hollow products are produced at high rates of speed. Twin sheet forming usually uses female molds. Both vacuum and pressure are used to form the part. The steps involved in this process are first two heated spaced sheets are fed between halves of an open mold, a blow pin will enter between the sheets, a very fast vacuum is introduced to each half of the tool and the mold will be closed. Both vacuum and pressure are introduced to allow the material to form the part. The mold then will open to allow the release of the part.

Twin Sheet Forming has many unique advantages over other types of forming. All thermoplastics that are available in extruded sheet form can be Twin Sheet formed. Materials used can be of different colors to offer a unique looking part. The material does not have to be of the same thickness and for strength, the part can be foam filled after forming. The cost of the tooling is lower than that of blow molding and can offer design features that will produce both a rigid part and one that is lightweight. Twin Sheet parts can also be produced at a faster rate, lower cost and higher volumes than that of rotational molding. You will also achieve a more uniform wall thickness and consistent part over rotational molding.

At Hagans Plastics, the process does not stop at forming a part. With our advanced technology, we can also offer additional related services such as deburring, drilling and light assembly. Our forming quality has put the parts made into industries such as aerospace, automotive, electronics, medical, food, consumer products, and even on the space station.